Dedicated Feeding System CFM-8 Liquid Gel Capsule Filling Machine Latte Base Cup

Product Features

.Speed: up to 290 capsules/min

. 8lanes

. Excellent production efficiency

. Minimal maintenance requirement

. Dedicated feeding system

. Extremely precise dosing to assure correct produce weight

. Possible tailor-made solutions according to capsule configuration

Product Picture

Sample Bag Picture

Product Packaging Scope

Machine Configuration

| Product number | CFM-8 |

| Applicable cup type | Latte base portion Cup (customizable) |

| Sealing material | Aluminum foil film |

| Control System | PLC+bus communication |

| Total power | 220V/50Hz (voltage can be customized) |

| Gas demand | 0.7Mpa |

| Overall line efficiency | 160 p/m (40p/l/p) |

| Filling accuracy | 6g±0.15g (powder) |

| Filling method | Servo custom screw |

| Applicable raw material characteristics | Powder granule liquid |

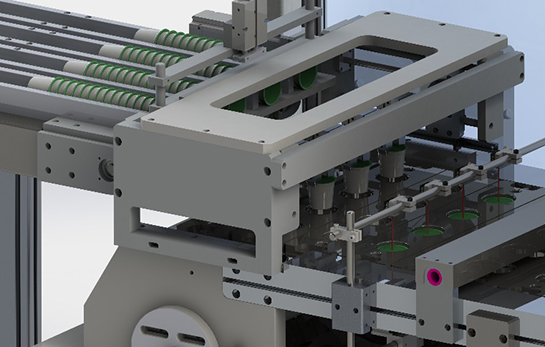

Machine Parts Diagram

1. Drop Cups Structure

Alternative 1:

Straight drop cup through the straight feed pipe, (estimated 300-400 cups) the working time is only 15 minutes, low material level automatic alarm through the buzzer call, manual feed.

Alternative 2:

Our products are horizontal conveying cup body structure, using type 0 belt conveying by unloading motor control, machine speed can be synchronized with the canned line speed, storage structure adopts warehouse structure, the maximum saving of manual feeding cycle and time, and can achieve a single feeding time control in 1.5 hours, very fast

Alternative 3:

Centrifugal disc structure, rotating conveying synchronous canned line speed, storage structure adopts bin body, the maximum saving of manual feeding cycle and time, can realize every 3 hours to control the feeding time, suitable for "automatic production line demand".

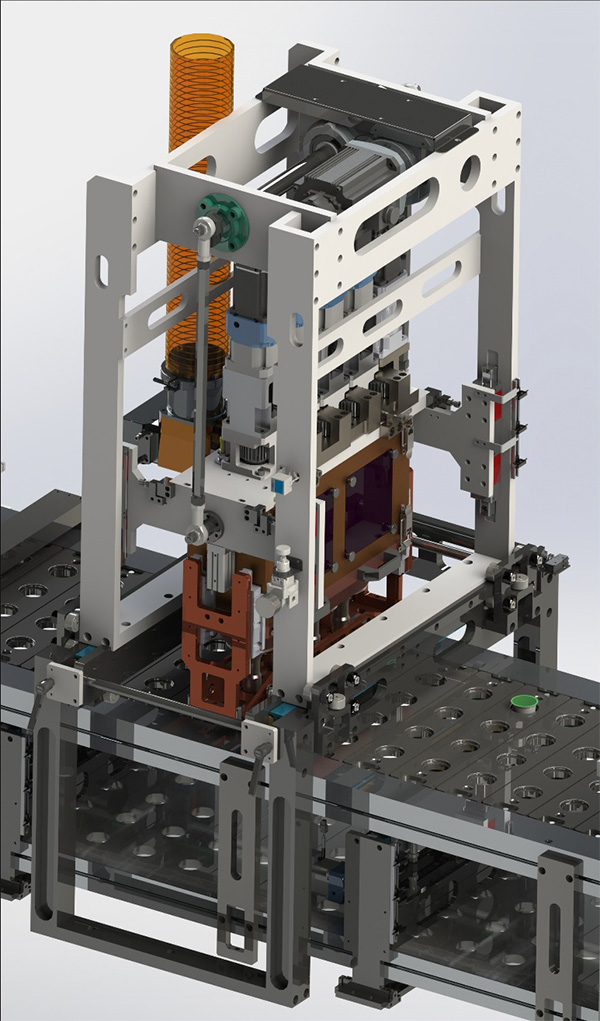

Fill the structure

Ensure sanitation, full servo screw filling system

Filling system adopts full servo drive control, only need to manually set the filling amount, without complex setting can achieve a key parameter adjustment. Under the action of servo mechanism, precise control of each filling amount, improve the product pass rate ≥98%. Professional design team based on years of accumulation of a large number of raw material particle size experimental parameters and data, according to the customer's material characteristics, to provide the most reasonable screw parameters.

After putting the capsule into the machine module board, there is a photoelectric sensor to detect the capsule. No capsule, no filling, no tamping or unsealed.

Filling system with servo screw conveyor

Tamp the powder to make the powder surface smooth, and clean the top edge of the capsule for better sealing.

Optional uv sterilization lamp and anti-static device, clean filling, filling precision is higher.

Application